Outdoor electronics are becoming more common in many fields. This means we need better ways to protect them from the environment. Waterproof polyurethane potting is a key solution, creating a strong shield against moisture, dust, and extreme temperatures.

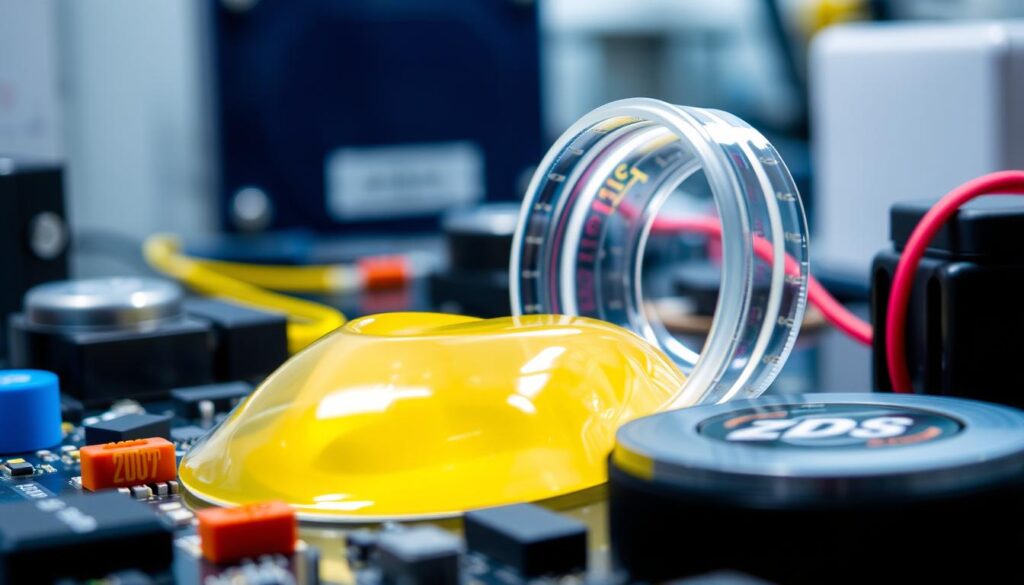

This method makes outdoor electronics last longer and work better in tough conditions. At ZDS™, we know how important it is to use top-notch polyurethane potting compounds. Our waterproof potting solution is a favorite among both manufacturers and DIY fans.

Key Takeaways

- Waterproof polyurethane potting is vital for protecting outdoor electronics from environmental threats.

- This potting solution enhances the durability and reliability of electronic devices.

- High-quality polyurethane compounds are essential for effective potting.

- ZDS™ specializes in innovative solutions tailored to outdoor electronic needs.

- Both professionals and amateurs benefit from using waterproof potting solutions.

Understanding Waterproof Polyurethane Potting

Waterproof polyurethane potting is key to protecting electronic parts from the outside world. It uses a special polyurethane compound. This compound fights moisture, dust, and physical harm.

Polyurethane’s chemistry gives it special powers. It’s tough and sticks well to many surfaces. This is vital for keeping things together, even in tough outdoor spots.

Polyurethane is also very flexible. It works well in many electronic uses. Plus, it stands up to UV light, keeping devices safe for a long time. Knowing this helps makers and hobbyists see why waterproof polyurethane is so important.

To learn more about these benefits, check out ZDS™. They focus on quality and new ideas for protecting electronics.

Benefits of Polyurethane Potting Compounds

Using polyurethane potting compounds offers big benefits for protecting outdoor electronics. They create a strong shield against the environment. This makes them perfect for devices that work outside.

- Weather Resistance: Polyurethane acts as a strong barrier against moisture. This ensures that electronic devices work well in different conditions.

- Longevity: This durable material stops corrosion and damage from UV rays and extreme temperatures. It helps electronic parts last longer.

- Enhanced Performance: Potting compounds reduce vibration and shock on electronics. This helps prevent parts from breaking and boosts device performance.

Waterproof Polyurethane Potting for Outdoor Electronics

Using waterproof polyurethane potting for outdoor electronics is key. It helps devices last longer in harsh weather. Knowing how waterproof materials work can make devices work better and last longer.

Importance of Weather Resistance

Weather resistance is vital for electronic devices. Waterproof polyurethane potting keeps sensitive parts safe. It stops moisture and makes the device stronger.

Many things make weather resistance important:

- It keeps water out in wet places.

- It keeps devices working well in all temperatures.

- It stops snow and ice from damaging devices.

Protection Against Environmental Factors

Outdoor devices face tough conditions like dirt and dust. Waterproof polyurethane potting keeps these out. It has many benefits:

- It keeps dirt and dust away from important parts.

- It means less upkeep and a longer life for devices.

- It helps devices work well in all kinds of weather.

Choosing good waterproof polyurethane potting keeps devices working in bad weather. It makes devices more efficient and happy customers.

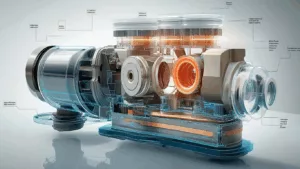

How Polyurethane Potting Works

Understanding polyurethane potting for electronics is key for top performance and reliability. This section dives into the encapsulation process. It also compares polyurethane with other potting materials.

Encapsulation Process Overview

The process of polyurethane potting involves several important steps. These steps create a strong, protective layer for electronic parts:

- Preparation: The surfaces of the components are cleaned and prepped to improve adhesion.

- Application: The polyurethane mixture is applied, often using a pouring or dispensing method for even coverage.

- Curing: The potting compound is allowed to cure, forming a solid, waterproof layer that covers the electronics.

Comparison with Other Potting Materials

Polyurethane potting stands out, but knowing its benefits requires comparing it with other materials:

| Property | Polyurethane | Epoxy | silicone |

|---|---|---|---|

| Flexibility | High | Medium | High |

| Adhesion | Excellent | Good | Fair |

| Water Resistance | Outstanding | Good | Fair |

| Durability | High | Very High | Medium |

This comparison shows that while epoxy and silicone have their benefits, they might not match polyurethane’s flexibility and adhesion. The right material is essential for long-term protection and function of electronic devices, even in tough environments.

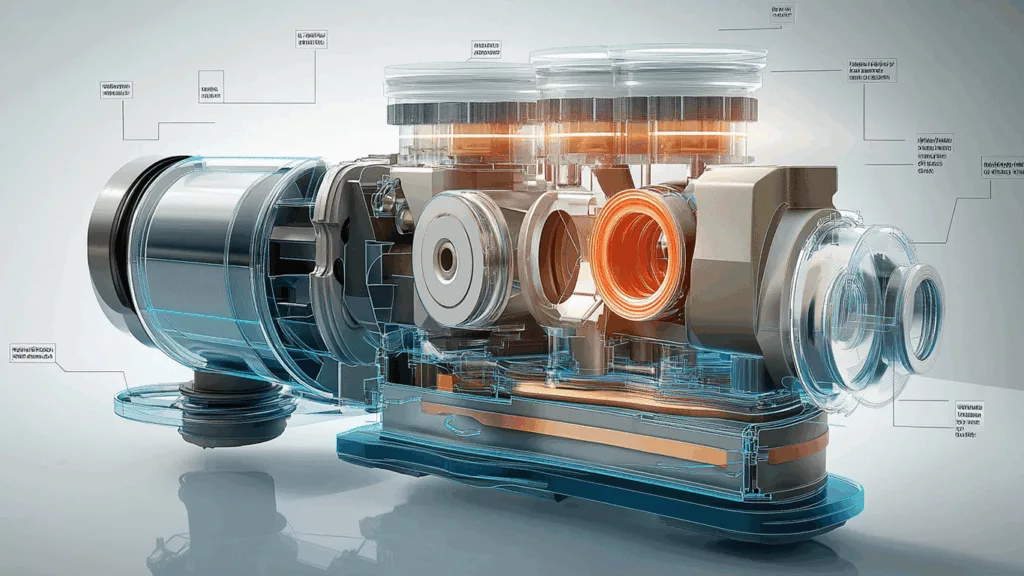

Applications in Outdoor Electronics

Waterproof polyurethane potting is key for outdoor electronic devices. It makes them work better and last longer. As tech gets better, so does the need for this potting solution. We look at how it works in different places.

Common Outdoor Electronic Devices

Many outdoor devices need good protection. Here are a few examples:

- Solar panels: They need strong protection against the sun.

- Street lighting systems: They keep out moisture and dust.

- Weather stations: They keep sensitive parts safe in all weather.

Performance in Diverse Environments

Waterproof polyurethane potting works well in many places. It stays strong and does its job. Here’s how it does:

| Environment | Performance Metrics | Durability Rating |

|---|---|---|

| Tropical climates | Withstands high humidity and temperatures | Excellent |

| Temperate climates | Resists moisture and temperature fluctuations | Good |

| Arid environments | Prevents corrosion and dust ingress | Very Good |

Choosing the Right Polyurethane Potting Solution

Choosing the right polyurethane potting compound is key. It depends on the project’s needs. You need to look at what each waterproof potting solution offers.

Key Considerations for Selection

When picking a polyurethane potting compound, think about a few things:

- Environmental Requirements: Check if the area will be wet, very hot, or cold, or if it will be exposed to chemicals.

- Viscosity: Think about how runny the compound is. Thicker ones might not get into tight spaces well.

- Cure Time: Look at how fast it sets. Faster ones can save time on your project.

- Thermal Properties: Know how it works in different temperatures. This ensures it works best.

Tips for Application

Applying a polyurethane potting compound well needs focus. Here are some tips:

- Surface Preparation: Make sure the surface is clean and dry for better sticking.

- Mixing Instructions: Mix it as the maker says to keep it effective.

- Application Method: Use the right way to apply, like pouring or brushing, for even coverage.

- Curing Conditions: Keep the right temperature and humidity while it cures for the best results.

| Property | High Viscosity | Low Viscosity |

|---|---|---|

| Penetration Ability | Poor | Excellent |

| Cure Time | Longer | Shorter |

| Application Method | Brushing | Pouring |

| Temperature Sensitivity | Higher | Lower |

By considering these points and following the application tips, you can make sure your waterproof potting solutions work well and last long in electronic projects.

ZDS™: A Leader in Potting Solutions

At ZDS™, we’re all about improving waterproof polyurethane potting for electronics. Our focus on quality and innovation has made us a key player. We’ve built a reputation for excellence, creating potting compounds that meet outdoor electronics’ unique needs.

Company Overview

ZDS™ was founded on the values of quality craftsmanship. We’ve grown to meet the high standards of the electronics world. Our team works hard to develop solutions that are both reliable and durable. Our waterproof polyurethane potting for electronics is designed to protect against harsh environments.

Products and Services Offered

We provide a wide range of products and services for different needs:

- High-performance polyurethane potting compounds for top-notch waterproofing.

- Custom formulations to fit specific industry needs, extending outdoor electronic device life.

- Technical support and consultation to help clients choose the best potting solutions.

Our waterproof polyurethane potting for electronics is known for its excellent shielding. We make sure each product meets our high standards. This makes them perfect for tough environments that need strong protection.

| Product | Key Feature | Application |

|---|---|---|

| Polyurethane Compound A | UV Resistant | Outdoor Lighting |

| Polyurethane Compound B | High Thermal Stability | Automotive Electronics |

| Polyurethane Compound C | Flexible Formulation | Consumer Electronics |

Best Practices for Waterproof Potting Application

When you apply waterproof polyurethane potting to outdoor electronics, it’s key to follow best practices. This ensures your sealed components work well and last long. The right application techniques are vital for the potting material’s success.

Cleaning the surface is the first important step. Make sure components are clean and free of dirt. Any dirt or moisture can ruin the bond. Using a cleaner made for electronics can help a lot.

Then, using the right application methods is important. Try to apply the potting material evenly. This helps cover all surfaces well and avoids air pockets. Air pockets can trap moisture and harm the seal.

Lastly, controlling the curing conditions is critical. Watch the temperature and humidity closely during curing. Following the manufacturer’s guidelines can make a big difference. It helps the potting material work as it should.

For more information on products that meet these standards, check out ZDS™ polyurethane potting solutions. They offer strong products for different challenges and needs. This ensures your electronics stay safe.

| Best Practice | Description |

|---|---|

| Surface Preparation | Thoroughly clean components to remove contaminants for better adhesion. |

| Application Techniques | Aim for an even and smooth layer of potting material to prevent air pockets. |

| Curing Conditions | Monitor temperature and humidity to achieve optimum curing results. |

Challenges and Solutions in Waterproof Potting

Waterproof potting solutions can face several challenges during use. Knowing these challenges helps us find ways to succeed in outdoor electronic encapsulation. Common problems include:

- Bubbling or uneven surface applications: This often happens because of bad mixing or application methods.

- Complications arising from environmental factors: Temperature and humidity can greatly affect how well the waterproof potting solution cures.

To tackle these challenges, we need to know the best practices in the field. Here are some solutions:

- Ensure proper mixing: Stick to the manufacturer’s mixing ratios to avoid bubbles and get a smooth finish.

- Monitor environmental conditions: Do the potting in the best temperature and humidity to prevent problems.

- Use appropriate application techniques: Apply even layers for uniform coverage and to reduce surface flaws.

By using these strategies, both manufacturers and DIY fans can improve their outdoor electronic encapsulation. This ensures their work is reliable and lasts in different weather conditions.

Real-World Case Studies

At ZDS™, we’re proud to share how waterproof polyurethane potting works for outdoor electronics. These stories show the challenges manufacturers faced and how we helped. They prove our weatherproof electronics potting really works.

A big name in the auto world had a problem with corrosive environments harming their electronics. Using weatherproof electronics potting from ZDS™ fixed this. It not only protected the devices but also made them work better and last longer.

Another company, focused on outdoor lighting, wanted their systems to last longer in bad weather. They used our special potting solutions and saw a big drop in failures. This made customers happier and cut down on warranty claims. It shows our products are built to last.

Here’s a quick look at what we’ve helped with:

| Case Study | Challenge | Solution | Outcome |

|---|---|---|---|

| Automotive Supplier | Corrosive environments | Weatherproof electronics potting | Improved longevity and performance |

| Outdoor Lighting Company | Harsh weather conditions | Customized potting solutions | Reduced failure rates, higher satisfaction |

These examples show how important waterproof polyurethane potting is for outdoor electronics. Companies that use these solutions see better reliability and performance. This shows how vital advanced materials are in today’s tough environments. For more on thermal conductivity potting, check out this link.

Conclusion

Waterproof polyurethane potting is key for outdoor electronics. It makes devices last longer and work better in tough weather. Polyurethane keeps moisture, heat, and physical damage away from sensitive parts.

This technology is used in many outdoor devices. It helps keep things like phones and solar panels working well. It’s a smart choice for makers who want their products to last.

At ZDS™, we’re proud to offer top-notch potting solutions. Our focus on innovation and quality makes us a leader. Choosing ZDS™ means you’re picking quality and reliability for your products. This leads to happier customers.

FAQ

What is waterproof polyurethane potting?

Waterproof polyurethane potting is a way to protect electronic parts. It uses a special polyurethane compound to make a waterproof shield. This shield keeps outdoor electronics safe from moisture, dust, and UV rays.

How does polyurethane potting compare to other potting materials?

Polyurethane potting is more flexible and sticks better than epoxy and silicone. It also lasts longer in different weather conditions. This makes it perfect for outdoor electronics.

Why is weather resistance important for outdoor electronics?

Weather resistance keeps outdoor electronics safe from moisture and dirt. Waterproof polyurethane potting creates a strong barrier. This barrier helps devices handle harsh weather like rain and snow.

What types of outdoor electronic devices can benefit from potting?

Many outdoor devices use waterproof polyurethane potting. This includes solar panels, street lights, and weather stations. These devices get better protection against the environment, lasting longer and working better.

What are the key considerations when selecting a polyurethane potting solution?

When picking a polyurethane potting solution, think about the environment, viscosity, cure time, and heat resistance. Choosing the right one ensures your devices are well-protected and work well outdoors.

How can I ensure successful application of waterproof potting?

For a successful application, make sure the surfaces are clean and dry. Apply the potting material smoothly and evenly. Also, control the curing conditions, like temperature and humidity, carefully.

What are some common challenges in waterproof potting applications?

Common problems include bubbles or uneven surfaces. These can happen if the mix is wrong or if the environment is not right during application. Knowing these issues and following best practices can help solve them.

Can you provide examples of real-world success using polyurethane potting?

Yes, we have many case studies of successful waterproof polyurethane potting in outdoor electronics. Each study shows how we solved specific problems. This proves our products are reliable.